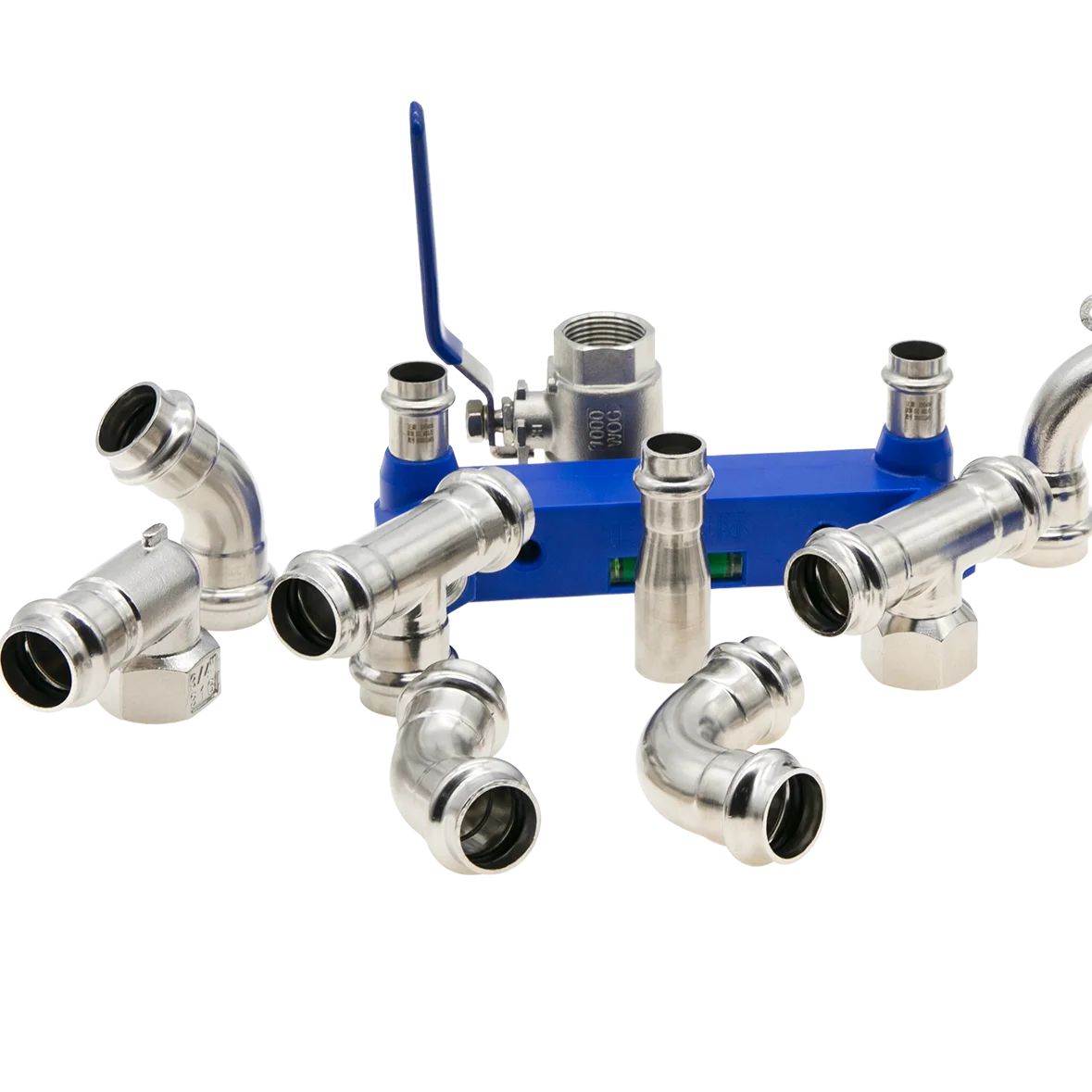

Have you ever thought about how metal and plastic combine together to make a car or building? An example of an interesting and valuable way to combine these materials is the so-called press method. Press fits occur when two materials are pushed or “pressed” together in hopes that they stay put, fitting snuggly into one another forming a single solid piece. One of the press fit we saw being used more frequently is … Stainles steel press fit. It is a connection that does not require the normal welding or glue, which can take extended periods for it to set and secure but one makes use of force in joining stainless steel pipes; immunity joints.

Here are some fine reasons why stainless steel press fit should be on your feature list for the next project you work. To start off, It is a very fast way to assemble materials. By this, I mean that it is only a matter of seconds to press two pipes together which makes the task more quickly done than having them welded. That means you are able to save a great deal of time if they work on your project. The second is that the joint theyre providing being made with stainless steel press fit actually makes for an incredibly strong fitting. The pressure that comes with the process also makes it so resistant, very important for a good support and security. And finally, stainless steel press fit looks great when fixing materials together. As opposed to using welding that often produces hazardous chemicals and fumes, stainless steel press fit does not produce these pollutants, making it easier on the environment.

With improvements in technology, stainless steel press fit is even more effective today as a way of connecting materials. Using special computer programs to design and test the press fit joint is an important advance. This allows engineers to really test and know the joint beforehand without creating one further down the line, saving both time and money in doing so. The other new way of automatically glue materials without needing workers to press the material is by using machines that could apply hydraulic pressure down on both sides of two layers. This simplifies and speeds everything up while guaranteeing that each joint is of a consistent quality.

Process of Stainless steel press fit - The method is simple seriously with stainless, but very basic. A machine is used to pressurize a stainless pipe or tube so that it fits snugly on another pipe or tube. The joint stays under pressure until it cools, making sure the materials have stuck together well. Another advantageous way of connecting this. For one, no dirty chemicals are required to bond materials together in this way. Second, by the virtue of using pressure it creates a strong bond with everything being connected. Finally, the whole point is short and can be done with minimal added tools or materials so its a very quick process.

Stainless Steel press fit is very expansive as it can be used in a wide variety of places and applications. Buildings: In buildings, stainless steel pipes are often pressed together and connected in a way that is both reliable and durable; plates.gameObject transform). And there must be sturdiness in plumbing systems, as these are long-term solutions. Stainless steel press fit is perfectly applicable for the manufacturing of stunning handrails and fences that are both tough as well as appealing. One of the most common applications is in automotive. In automobiles, for instance, stainless steel is press fit into the system to connect different parts of it. This is important as these component should be tough and heat resisting parts. Stainless steel press fit also finds application in the construction of heavy machinery (such as tractors and bulldozers) that must be strong and tough.

CHNCON has a high-level reputation within China. The quality and the service are of the highest level. CHNCON is accredited with ISO9001, OHSAS18001, ISO14001, DVGW, ICC-ES, WRAS, CSTB and stainless steel press fit certifications etc. We are committed to bringing new pipeline products that have the benefits of safe, healthy efficient and cost-effective to around the world.

Chncon is a reputable RD team which has more than 10 engineers. We can not only provide stainless steel press fit, however we also offer custom services. In the RD phase of new products we will try the best we can to offer professional advice and suggestions to help your ideas be executed.

stainless steel press fit is home to 60 production lines and an outstanding capacity of production which is more than 300 000 pieces of pipes and fittings monthly produced This provides a solid promise of timely delivery At present Chncon' business have reached more than 500 cities in China and exported over 50 regions and countries benefiting nearly 20 million families Excellent quality fast manufacturing time and attentive customer service Chncon is a wonderful choice in pipeline area

Chncon is a specialist in stainless steel pipe systems for over 20 years. The plant is located in 23000 square meters. Chncon has four product lines that include more than 10,000 pipe fittings that meet every customer's requirements. Chncon is a result of more than 30 certificates at home as well as stainless steel press fit.

Copyright © Zhejiang Zhengkang Industrial Co., Ltd. All Rights Reserved - Privacy Policy