Welding SS pipes wrong and right ways to do it! Welding is a process that used to connect two metal pieces between heat and pressure called SS tube welding. Practice it with care as a skill does. You have to be taught how to do this in order to master the skill. There are useful tips and tricks that might assist in improving your SS tube welding process, resulting again with a solid twitch weld without fail. In this part by AllinOneblog we are going to let you know about some great welding techniques, which can be accomplished when working on SS tubes.

Welding stainless steel tubes is a skill, an Ethernet-job testament to practice. This is why it is not a overnight practice. To protect yourself from any accidents, you need to use the correct tools when welding SS tubes. To pull it off, you miami need a welding machine and also irrespective of where in wisconsin the world are wanting to work with steel strips. It is very necessary to have these accessories as they will protect you from dangers like sparks, heat and more while welding.

With the proper tools and clean metal at your disposal, not you just need to choose which welding technique is right for that specific project. SS tubes can be welded in several different ways. Examples of techniques are gas tungsten arc welding (GTAW), gas metal arc welding (GMAW or MIG), and shielded metalarcwelding(SMAWellis). All these techniques have their own advantages and are suitable to certain conditions, so it is important that you choose the correct one depending on your needs.

Properly make this weld, is the other most important thing about using a stick for it. Arc length is a part to recognize when welding. An arc length, as its name implies is the distance between your welding tool and metal that you are working with. If it is too close to the hot metal, that might work very well but there are problems if you want more than 3cm of distance between your nozzle and the part due to other related factors (like sustainability). Alternatively, if the arc length is too large then that weld may be weak and not hold properly.

And secondly, always use the correct manner of occupation. There are a number of techniques for welding SS tubes but some may work better with certain types of tubing and projects than others. It may be best to experiment with each of them and see what brings you the most success. Play around and figure out what works for you!

Welding processes include risks as well, so safety is no less important. ALWAYS Properly wear welding helmet and protective gloves in jacket form while working. Keep your workspace clean and orderly so accidents do not occur. A safer work place makes it easier to concentrate on your projects without any worries of the inevitable injury.

Another good process is gas tungsten arc welding (GTAW). This method is one of the fastest and easiest welding processes using a wire which feeds from a spool continuously. For welding thin sheets of SS tube GMAW can be a perfect fit, and you end up with clean, smooth welds which require very little finishing work to make everything look tidy.

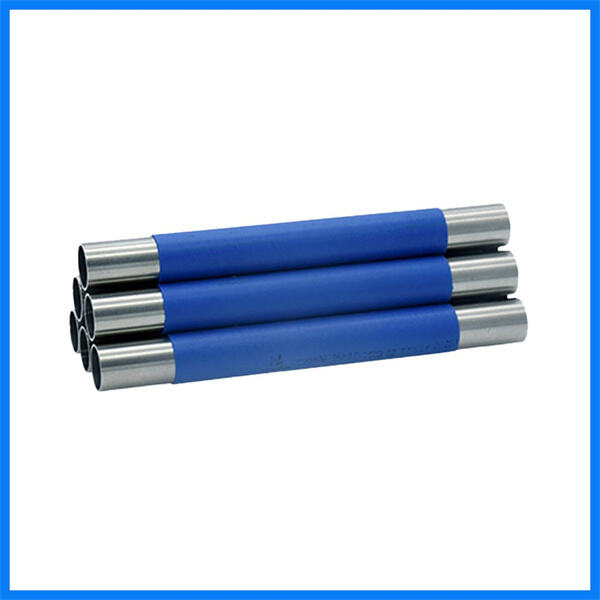

Chncon is a reputable RD team which has more than 10 engineers. We can not only provide ss tube welding, however we also offer custom services. In the RD phase of new products we will try the best we can to offer professional advice and suggestions to help your ideas be executed.

CHNCON has a ss tube welding reputation within China. The quality and the service are high-end. Our company is accredited with ISO9001, OHSAS18001 and ISO14001 certifications, DVGW, ICC-ES, WRAS, CSTB, WATERMARK and more. We are dedicated to providing new pipeline products that have important advantages, including being safe, energy-saving, and economical.

Chncon factory is home to 60 production lines with an impressive capacity to produce over 300 000 pcs of fittings and pipes each month produced This allows for a good promise of timely delivery Today Chncon' business have expanded to more than 500 cities in China and exported to more than 50 regions and countries with a total of 20 million facilities Chncon is a top choice for pipelines offers superior quality ss tube welding production time and professional service

Chncon has been a specialist in stainless steel pipe systems for over 20 years. The facility is 23000 square metres. Chncon offers 4 products, with more than ss tube welding that can meet the requirements of every customer. Chncon has been achieved for more than 30 accreditations at home and overseas.

Copyright © Zhejiang Zhengkang Industrial Co., Ltd. All Rights Reserved - Privacy Policy