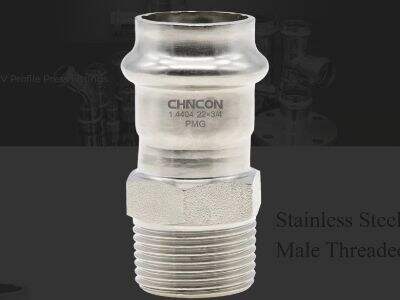

Stainless Steel Press Fittings are awesome for stuff like pipes and tubes because they don’t rust! These press fittings are made by CHNCON and they are excellent when it comes to being able to remain strong even when wet and in harsh environments. Yet, have you ever asked yourself why stainless steel is so strong and never gets all rusty? Well, really, it has to do with some pretty cool science around how it is made and what it is made of

Studying about the chemistry of stainless-steel press fittings

Stainless steel is not your average steel. There’s some extra special stuff mixed in to help it fend off rust. Description of Stainless Steel Press Fittings CHNCON stainless steel press fittings are constructed of a 304 stainless steel material mix containing iron, chromium, nickel, and other elements in trace quantities. And the chromium is super important because it actually forms a protective layer on top of the steel. This is what keeps water and air from creating rust

Corrosion resistance in detail for stainless steel

So, what is it about stainless steel that makes it so resistant to rust? It’s mostly thanks to that chromium we discussed. When stainless steel is exposed to oxygen, chromium is the metal that reacts with it and forms a tough, thin layer known as chromium oxide. This layer adheres to and prevents rust from spreading. It’s a little like a coating that shields the steel underneath

The influence of an alloy The influence of an alloy on the corrosion resistance of press fittings

The combination of metals used in stainless steel is called an alloy. CHNCON is made of a special kind of alloy which has the correct amount of chromium and nickel to ensure that the stainless steel does not rust and is super strong. Without enough chromium, the protective layer won’t form properly, and the steel would be prone to rust. So it’s really crucial to get the mix between the alloys just right

Revealing how stainless steel mere exposure leads to resistance in harsh environments

Stainless steel press fittings can withstand just about anything, from being plunged into salty water to soaked in chemicals. That’s thanks to that protective chromium oxide layer we mentioned. And if the layer does get damaged, more chromium in the steel will react with oxygen and restore the layer. That is the reason why we use press fittings CHNCON in many different industries that come with high demands

Why stainless steel press fittings are the best for lasting performance 101

When you choose stainless steel press fittings from CHNCON, you’re selecting a product that will have a really long life – even in the most tough environments. They require very little care thanks to their impressive rust resistance, and they last a long time. They are therefore a smart material to use for things that have to be reliable and strong, like water pipes and other key structures

So all in all — when you really stop and think about it — all this science in stainless steel press fittings is actually quite unbelievable. It’s just the perfect combination of metals and some pretty neat reactions that occur to keep that steel strong and rust-free

Table of Contents

- Studying about the chemistry of stainless-steel press fittings

- Corrosion resistance in detail for stainless steel

- The influence of an alloy The influence of an alloy on the corrosion resistance of press fittings

- Revealing how stainless steel mere exposure leads to resistance in harsh environments

- Why stainless steel press fittings are the best for lasting performance 101