Bending stainless steel tubes means changing them into different shapes and angles. It is essential in industries such as the automotive industry, construction, and other industries, where it is crucial to bend tubes to ensure that everything runs properly. Nevertheless, it is difficult to bend a stainless steel tube exactly the way you need it. One has to practice a lot and also have the necessary tools to bend it accurately. There are several ways to bend a tube, and each has its advantages and disadvantages. One of the most common techniques is rotary draw bending. It uses a special tool that is called mandrel to keep the tube in its shape while being bent. The next method is press bending. The press brake is a special machine used in this process. Thickness, shape, and accuracy of stainless steel tube bending from CHNCON for a particular job need to be considered when bending tubes.

The selection of tools for CHNCON bending stainless steel tubes is essential. Those tools might be different based on how you are bending. Hand-held tube benders are one of the simplest type of tools and work well for creating small bends. But hydraulic or electric machines are better for making complex shapes and angles. Tube Size and Thickness —the larger the tube, which means higher pressure resistance involved will weigh in on what tools can be used. Having the right gear is an essential for an equal bend if you want to perfect your work.

There are so many benefits of using bending stainless steel tubes in different tasks and industries. Making an array of shapes and angles is a major plus. The automotive and aerospace sectors are prime examples where bent tubes for exhaust systems, fluid transfer lines, etc., must be precisely formed. Bending stainless steel tubes b yCHNCON are also necessary so that there is no interruption in the flow of liquids or gases inside them as well. Furthermore, it is only resistant against the elements and corrosive materials when constructed using high-quality stainless steel not-found in most commercial-grade grates. Therefore, it is a good option for many industrial applications.

Quality Control — One Part of Bending Stainless Steel Tubes Better And More Accurately This could be done by an everyday tube check to make certain tubes the meet specs. Also, the tubes must be tested for leakage and cracking to enable their integrity. These tubes can be bent to precise dimensions by machines with the aid of specialized computer programs. This is to say that they are not going to be any less wastage, and better results. Consequently, processing quality and efficient bending play a key role in the production of high-quality components according to the required standards.

The stress bending of stainless steel tube is a process that critical in many precision jobs. To obtain accurate bends of the desired shape, it is necessary to use techniques such as rotary draw bending and press bending in combination with a selection of different footages depending on frequency — along with taking into account that tubes should be thick. Selecting the right 45 degree bend pipe and controlling quality mean stronger parts for end-use applications.

Chncon has a Stainless tube bending RD team that includes more than 10 engineers. We are not limited to providing traditional pipe fittings, but we also provide custom services. We'll provide the best advice and suggestions throughout the development and testing phase of a brand new product to assist you in achieving your goals.

Stainless tube bending is home to 60 production lines and an outstanding capacity of production which is more than 300 000 pieces of pipes and fittings monthly produced This provides a solid promise of timely delivery At present Chncon' business have reached more than 500 cities in China and exported over 50 regions and countries benefiting nearly 20 million families Excellent quality fast manufacturing time and attentive customer service Chncon is a wonderful choice in pipeline area

CHNCON and its high reputation in Stainless tube bending, the quality as well as the service are at the best in the industry. Our company is certified by ISO9001, OHSAS18001 and ISO14001 certifications, DVGW, ICC-ES, WRAS, CSTB, WATERMARK and many more. We committed to deliver new pipelines that offer significant advantages of healthy, safe economical, and energy-saving for everywhere in the world.

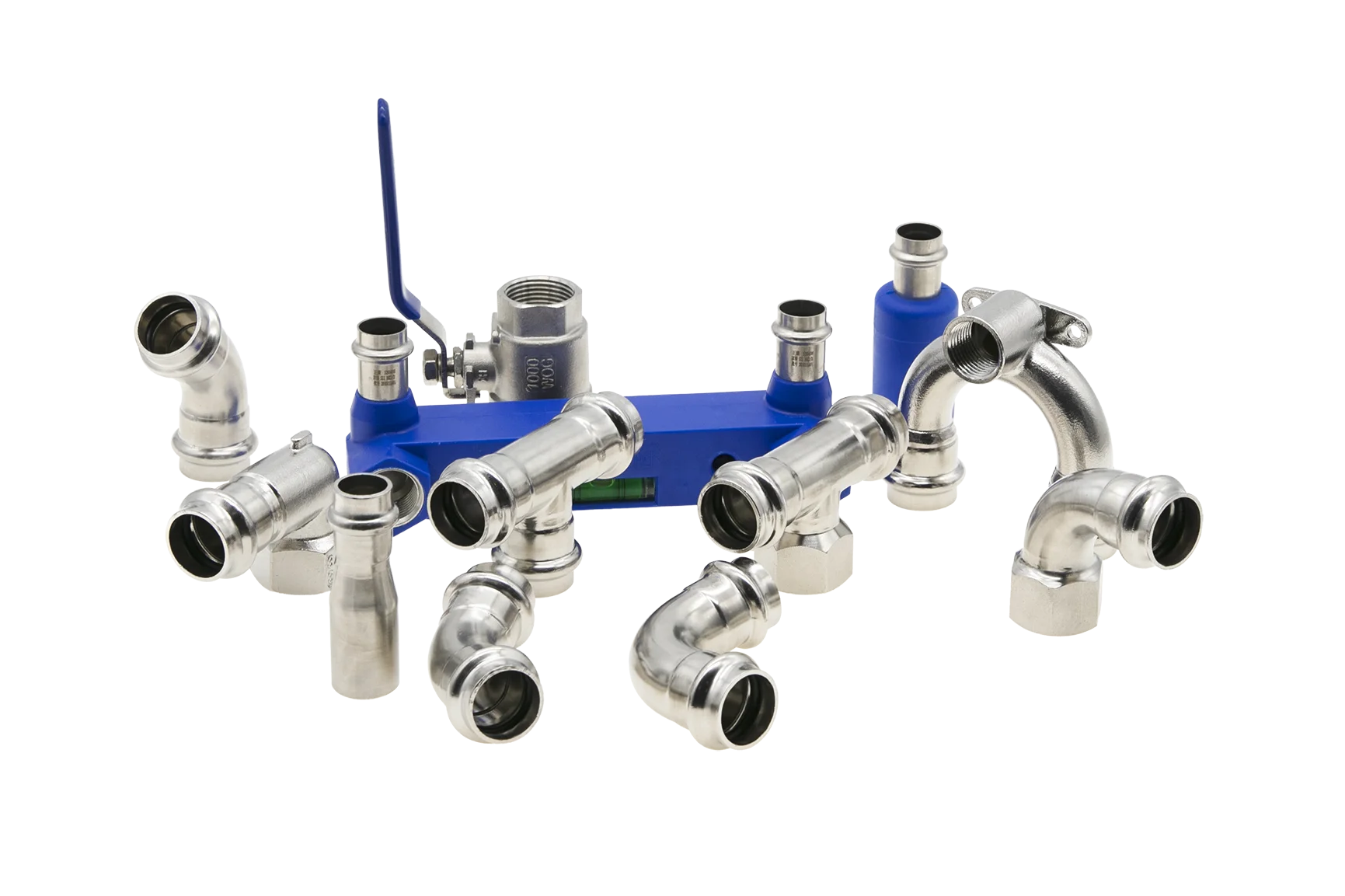

Stainless tube bending is a producer that specializes in the stainless pipeline systems made of steel for over 20 years with a manufacturing facility that covers 23000 square meters. Chncon offers 4 products, with over 10,000 fittings to meet the needs of all customers. Chncon is accredited for more than 30 certifications both in the United States and internationally.

Copyright © Zhejiang Zhengkang Industrial Co., Ltd. All Rights Reserved - Privacy Policy